Company Profile

Hebei Sunrise Hydraulics: Three Decades of Craftsmanship, Empowering the Global Hydraulic Industry with Made-in-China Intelligence

Founded in 1989, Hebei Sunrise Hydraulic Technology Co., Ltd. has specialized in the hydraulic field for over 30 years. With profound industry accumulation, it has been accredited as a National High-Tech Enterprise, a "Specialized, Refined, Characteristic, and Innovative" Enterprise, and a Provincial Technology-Based Enterprise. Adhering to the core philosophy of "Craftsmanship for Quality, Innovation-Driven, Customer First", the company has steadily grown from a local rooted enterprise to a globally deployed modern manufacturing benchmark with strong competitiveness in hydraulic valves and related supporting products, providing stable and reliable products and customized solutions for global customers.

Strength Foundation: Qualification Certification and Hardware Support

Boasting strong comprehensive strength, the company demonstrates remarkable core competitiveness: it has accumulated more than 50 patents, maintaining cutting-edge technological level in the industry; meanwhile, it has passed the ISO 9001:2015 Quality Management System, ISO 14001:2015 Environmental Management System, and ISO 45001:2018 Occupational Health and Safety Management System certifications, supplemented by multiple heavyweight qualifications such as Grade III Enterprise of Work Safety Standardization and Grade B Enterprise of Environmental Performance Evaluation. Fully implementing 6S on-site management, the company has laid a solid foundation for development through standardized and refined operations.

Located in the core area of Hebei's industrial agglomeration, the company covers an area of over 20,000 square meters, equipped with standardized production workshops, high-end R&D centers, and precision testing laboratories. Core technical talents account for a prominent proportion among more than 100 employees, injecting sustained momentum into technological upgrading, product innovation, and quality improvement, while providing solid guarantees for large-scale production and customized services.

Core Products: Multi-Scenario Coverage, Empowering Efficient Industry Operation

The company's core products cover four main series—hydraulic multi-way valves, wood splitter series valves, micro-excavator series multi-way valves, and micro-tiller series gearboxes—accurately meeting the application needs of engineering construction, agricultural cultivation, forestry operations, mining, and other fields. With core advantages of "compact structure, convenient operation, stable performance, wear resistance, and strong adaptability", the products can not only meet the requirements of standardized mass production but also provide customized solutions according to customers' specific working conditions, injecting efficient power into production operations of various industries and becoming a preferred partner for global customers.

Relying on strong comprehensive strength and product competitiveness, the company's products are exported to more than 10 countries worldwide, including the United States, Russia, Germany, Japan, and Australia, covering core markets such as Europe, America, Asia-Pacific, and South America, winning wide international recognition for China's hydraulic manufacturing.

Core Pillar: Precision Castings, Consolidating the Foundation of Quality

The Precision Casting Manufacturing Center is the core competitiveness of the company's whole-industry-chain layout. Focusing on the R&D and large-scale production of high-quality castings such as high-grade cast iron, ductile iron, and vermicular iron, its annual production capacity exceeds 5,000 tons. Equipped with cutting-edge testing equipment including direct-reading spectrographs, computer-controlled metallographic analyzers, on-site molten iron analyzers, and computer-controlled hydraulic universal testing machines, the center has established a full-dimensional traceability testing system covering raw material composition, molten iron purity, casting metallographic structure, and mechanical properties, controlling the quality of each batch of castings with millimeter-level precision and strict standards. Whether ensuring the independent controllability of the company's core products or providing high-end customized casting supporting services for external partners, it has won wide praise in the industry with excellent material performance and precise dimensional accuracy, becoming a trusted high-end casting service provider in the market.

Intelligent Manufacturing: Precise Control, Safeguarding Excellent Quality

In the production and manufacturing process, the company adheres to the development strategy of "Intelligentization, High Precision, and Large-Scale Production", equipped with more than 200 sets of high-precision professional machining equipment, including CNC lathes, high-end machining centers, high-precision grinders,

Company purpose

Reputation first, customer first

Reputation first, customer first

Quality first, customer satisfaction

Quality first, customer satisfaction

Time first, keep the promise

Time first, keep promises

Service first, warm and thoughtful

Service first, enthusiastic and thoughtful

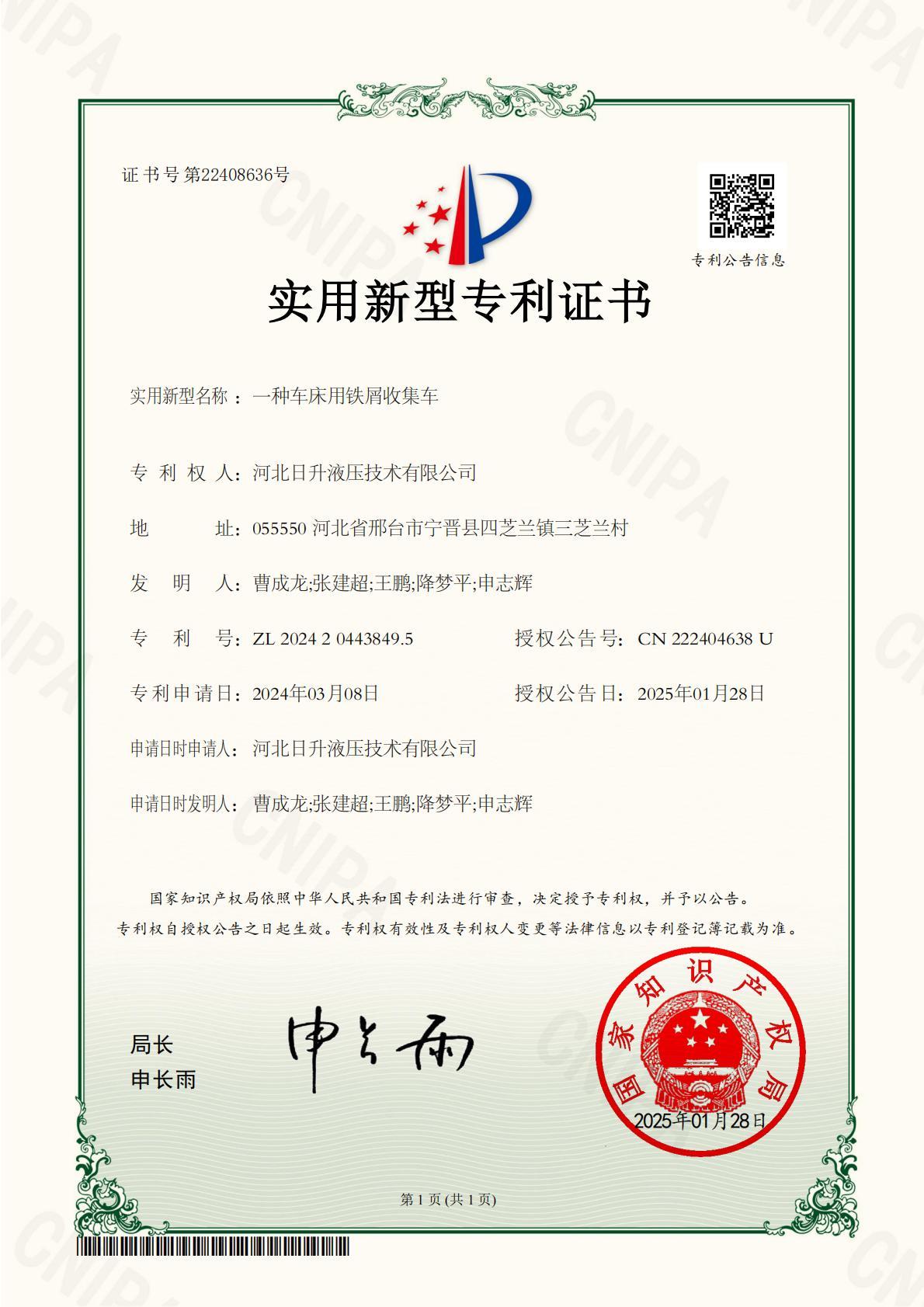

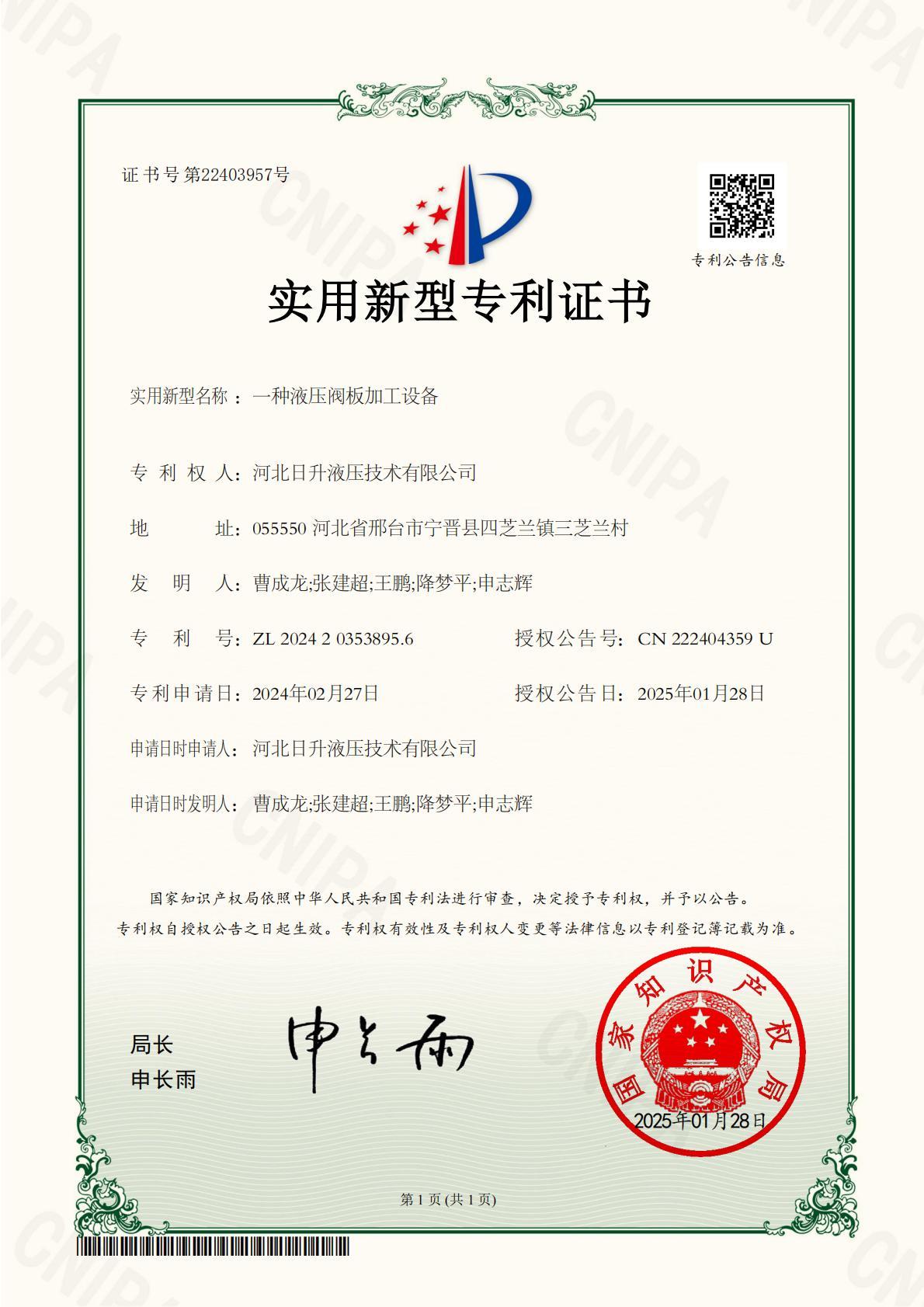

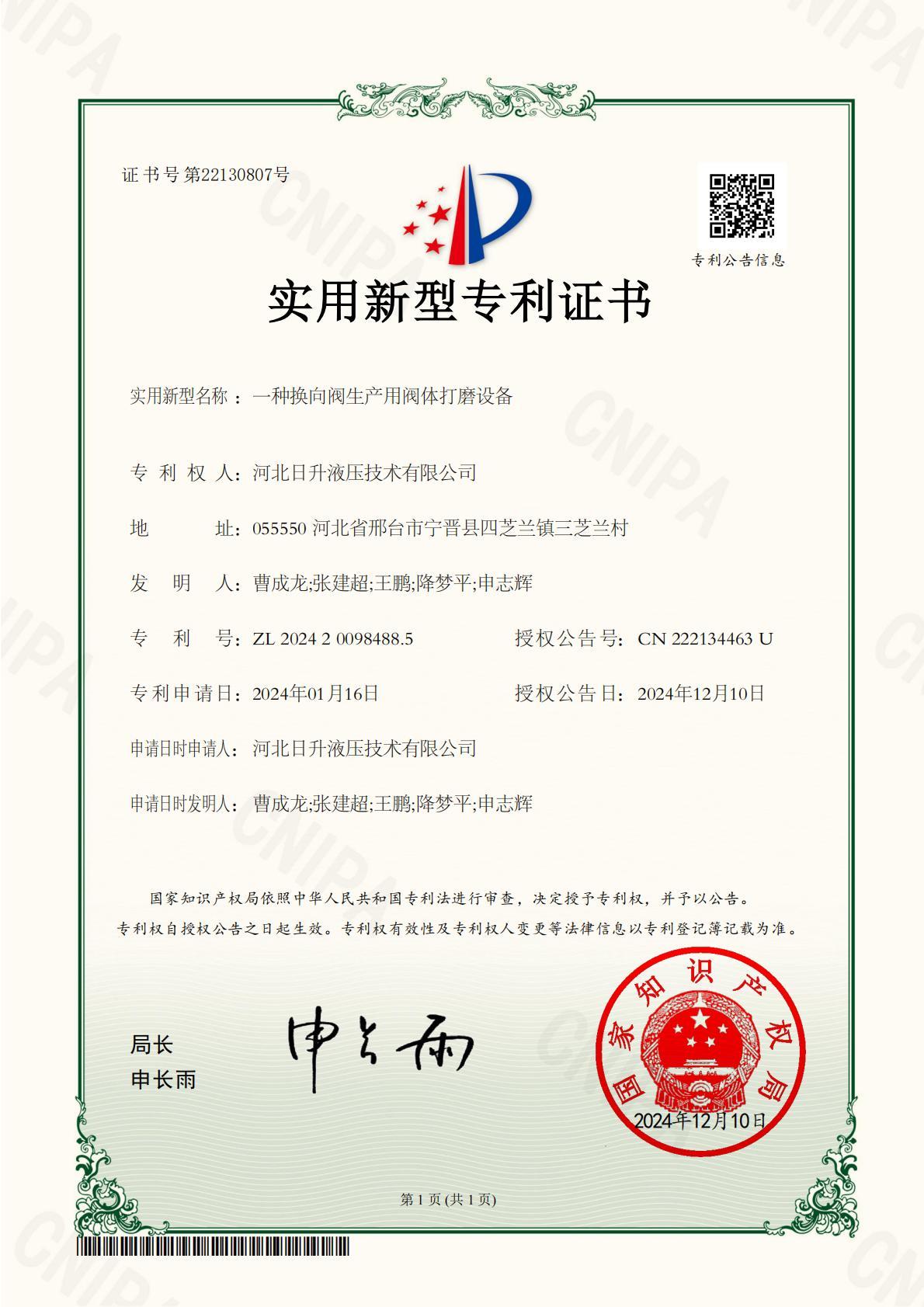

Qualification Honor

Risen Hydraulics (International Classification: 7)

Utility model name: A lathe swarf collecting vehicle

Utility model name: A hydraulic valve plate processing equipment

Utility model name: A valve body polishing equipment for the production of reversing valves

Utility model name: A device for detecting trace elements in reversing valve materials

Utility model name: A three-position four-way reversing valve